Vaccine Manufacturing Vaccine Production Process, On Demand Cell Free Biomanufacturing Of Conjugate Vaccines At The Point Of Care Prelights

Vaccine manufacturing vaccine production process Indeed recently has been hunted by users around us, perhaps one of you personally. Individuals now are accustomed to using the net in gadgets to view image and video data for inspiration, and according to the name of the article I will talk about about Vaccine Manufacturing Vaccine Production Process.

- Producing Prevention The Complex Development Of Vaccines Resources

- Vaccine Production Techniques

- Plos One Influenza Vaccine Manufacturing Effect Of Inactivation Splitting And Site Of Manufacturing Comparison Of Influenza Vaccine Production Processes

- On Demand Cell Free Biomanufacturing Of Conjugate Vaccines At The Point Of Care Prelights

- Fig S1 Flowchart Of Vaccine Formulation Storage And Delivery From Download Scientific Diagram

- Individualized Nhl Vaccine Manufacturing Process Overview Download Scientific Diagram

Find, Read, And Discover Vaccine Manufacturing Vaccine Production Process, Such Us:

- Schematic Of Vaccine Manufacturing Process Sanofi Pasteur Toronto Download Scientific Diagram

- Https Www Bio Fiocruz Br En Images Stories Pdfs Mpti 2013 Selecao Vaccine Process Technology Pdf

- Pharma Bio World

- Pandemic Influenza Vaccine Manufacturing Process And Timeline

- Towards Effective Covid 19 Vaccines Updates Perspectives And Challenges Review

If you re searching for Pfizer Covid Interim Analysis you've reached the right location. We have 104 graphics about pfizer covid interim analysis including images, photos, photographs, backgrounds, and more. In these page, we also have number of graphics out there. Such as png, jpg, animated gifs, pic art, logo, black and white, translucent, etc.

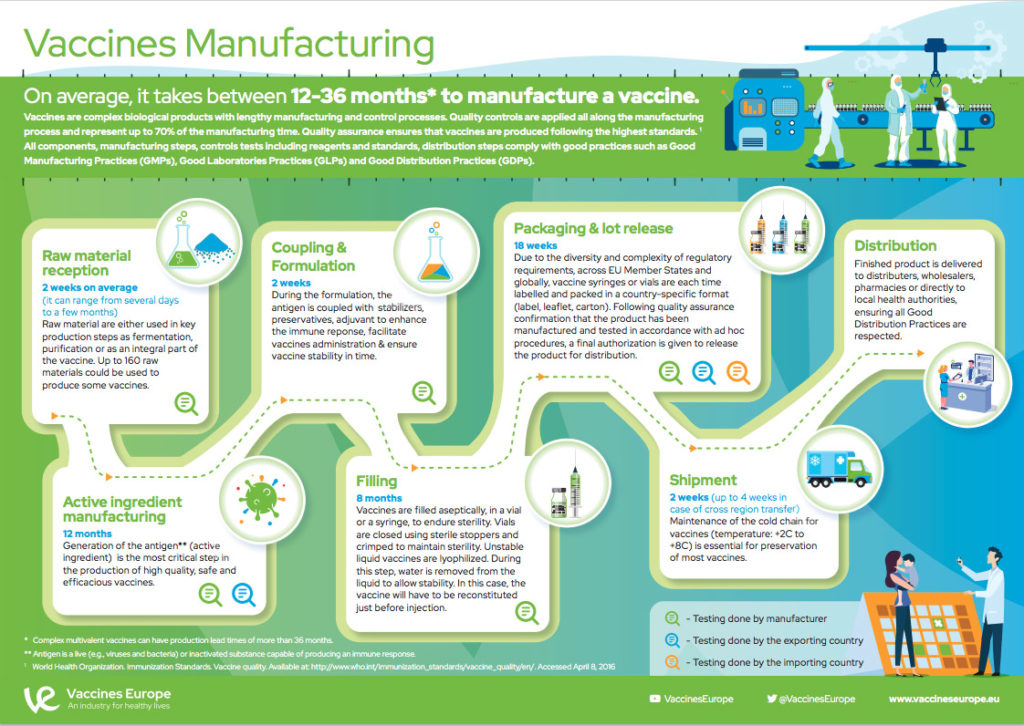

Traditionally manufacturers focus on identifying installed capacity for a particular production process to serve a specific market need.

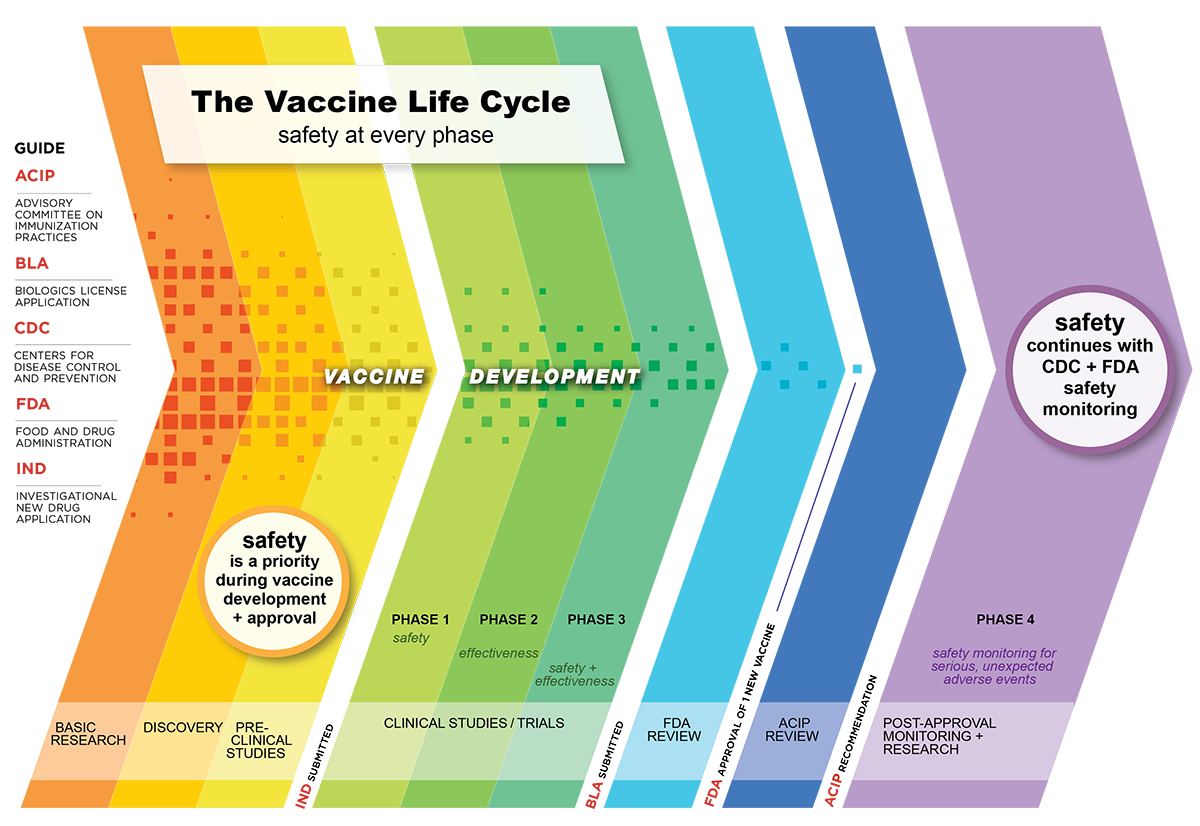

Pfizer covid interim analysis. We need to continually adapt production process to satisfy evolving regulatory demand which varies country by country. Vaccine production has several stages. Boriana marintcheva in harnessing the power of viruses 2018.

First the antigen itself is generated. Vaccine production in plants is already a fact due to advances of. Vaccines are basically meant to train and strengthen the immune system to develop resistance against anti bodies and illnesses by imitating an infection to create a natural immune response.

There are entire chicken farms in the us and around the world dedicated to producing eggs for the purpose of incubating influenza viruses for use in vaccines. This production method requires large numbers of chicken eggs to produce vaccine and may take longer than other production methods. The vaccine manufacturing facility represents a significant fixed and ongoing maintenance cost for the vaccine manufacturer.

A very attractive idea for alternative vaccine production and delivery is genetically engineering plants to produce vaccines that would be delivered to the human body as part of our diet ie by eating traditional fruits and vegetables. Manufacturing vaccine is a biological process where a very high level of expertise is required. Most of the active types of vaccines remain in the system as anti bodies even after they have completed their process of creating a stronger immunity system.

The production of a vaccine can take between 6 and 36 months vaccines manufacturing is a biological process where a very high level of expertise is required. Successful manufacturing of high quality vaccines requires international standardization of starting materials production and quality control testing and the setting of high expectations for regulatory oversight of the entire manufacturing process from start to finish all while recognizing that this field is in constant change 1. Viruses are grown either on primary cells such as chicken eggs eg for influenza or on continuous cell lines.

This requires careful assessment of market opportunity to determine optimal capacity. Vaccine for hepatitis b is successfully made in banana. Vaccine for cholera is successfully developed in potato banana is the ideal plant for oral vaccine production due to its excellent digestibility palatability and availability throughout the year.

We need to continually adapt production process to satisfy evolving regulatory demand which varies country by country.

More From Pfizer Covid Interim Analysis

- Vaccine Ingredients Uk

- Hpv Vaccine Singapore Where To Get

- Pfizer Vaccine Name

- Difference Between Dowagers Hump And Buffalo Hump

- Vaccine October 2020

Incoming Search Terms:

- Gmp In Vaccine Production Blog Celitron Vaccine October 2020,

- U S Vaccine Safety Overview History And How It Works Cdc Vaccine October 2020,

- How Are Vaccines Produced Vaccines Europe Vaccine October 2020,

- Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gctp Jbfq K3iwac1mhcwxqpxtkqslgg9rruhfoggfzcaqwxtykf Usqp Cau Vaccine October 2020,

- Advances In Purification Technologies Accelerate Vaccine Development American Pharmaceutical Review The Review Of American Pharmaceutical Business Technology Vaccine October 2020,

- Researchers Seek To Repurpose An Existing Manufacturing Platform To Produce A Covid 19 Vaccine Vaccine October 2020,